Movement joints, otherwise known as expansion joints and stress relieving joints are used within tiled surfaces to break a large area into separate sections. A tiled surface is rigid in its design, so if there is movement in the surface there will be damage to the tiles, if movement joints are not used.

The design of movement joints should be planned before tiling installation, to effectively enable each tiled section to move independently. To help you decide where to include movement joints in your next tiling project, we have put together this guide to fitting movement joints.

What are movement joints

Every tile is a solid material, with very little dimensional change despite the conditions in which they are laid. However, in some circumstances the area where the tiles are laid can change in size, due to factors such as settling, weight loading, traffic levels, moisture and thermal conditions. The surface will expand and contract, depending on changes in the environment which will inevitably transfer to the tiled surface.

Movement joint acts as a break within the tiled surface and are designed to absorb the various forces arising from the movement within the surface. The joints effectively create various tiled bays, which are large enough to absorb any differential movement. The result is a tiled surface which is able to withstand cracking, tenting and debonding from the substrate.

Depending on their location and function, it is possible to install intermediate, perimeter and structural joints. It is important to correctly install any movement joints, as if they are fitted in the wrong place they will not work.

Structural joints

These joints divide the surface, to prevent uncontrollable cracks. The width of a structural movement joint should be 4x the maximum movement expected, with 10mm being the minimum. For particularly wide joints, metal reinforcement can be used to protect the adjacent tiles and the sealant.

Perimeter joints

Perimeter joints are used to separate areas of the tiled surface, to ensure any movement does not compromise the tiling. If there is an obstruction or construction element which limits movement of the surface, a perimeter joint should be incorporated. The joint should be at least 6mm wide and should reach a depth of either the decoupling or separation layer. This is usually far less than the thickness of the adhesive and tiles, so there are no aesthetic problems when a good sealant is used.

Intermediate joints

Intermediate joints are designed to divide a large tiled surface into smaller sections, so that each independently moves when under pressure. They should be incorporated into all external tiled areas and within internal surfaces, where the tiling will come under stress from radiant heating, sunlight, building loads of structural movement. The joints should be at least 10mm wide and should be fitted to a depth level with the substrate below.

Movement joints in tiled walls

Any junction between flooring and a wall should be fitted with a movement joint, although you should also consider fitting joints in the actual wall. A tiled wall will be under constant stress which means there is a potential for movement, especially in the following situations:

• There is an existing movement joint within the wall structure. In this situation, the new movement joint should be at least the same width as the existing joint and should be fitted directly over the existing joint.

• Within internal and external corners, where the walls come under stress from vibration and thermal movement.

• In areas where tiling joins a different substrate, a movement joint should be used as a junction between the two.

• If tiling bridges are used in walls with different substrates, movement joints should be incorporated at each junction.

• If a tiled wall is particularly large, multiple movement joints should be included vertically and horizontally. The exact layout will depend on the actual building design, although you should aim to include joints at intervals of between 3m and 10m.

• If any wall is expected to come under significant stress from vibration or thermal stress, movement joints will need to be incorporated at regular intervals.

Movement joints in tiled floors

Including movement joints in a tiled floor will enable the surface to move without cracking. The type of movement joint required will depend on the use of the floor, the movement potential and the width requirement of the joint. The following are examples of tiling situations where a movement joint should be incorporated:

-

-

- • If a floor already uses movement joints in its construction, movement joints within the tiled surface should be included and aligned with the existing joints.

-

- • Joints should be included throughout a tiled floor surface, to create individually tiled sections. In general, the advice is to include joints at intervals of between 5m and 8m, depending on the conditions of the area.

-

- • If a floor has an underfloor heating system, movement joints should be fitted with a limited tile bay size of 25m². The joints should be positioned so that each heating zone is able to continue to perform separately.

-

- • Wherever a surface will come under particular stress from the subfloor, as the potential for movement will often be unknown. In many situations the age of the building may be unknown and the subfloor may not be completely dry. If you are in any doubt, it is advisable to include a movement joint.

-

- • Wherever the flooring is interrupted, such as the perimeter, pillars or where the floor meets the wall, a movement joint should be included.

-

• If a floor is installed above a supporting wall or beam, a movement joint should be placed directly above as the overall rigidity of the floor will improve.

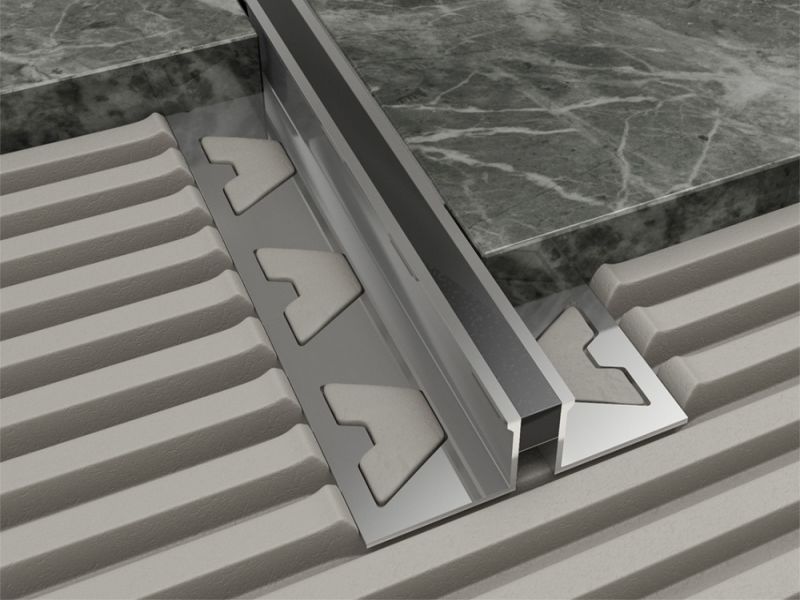

A variety of movement joint designs

There are a variety of movement joint designs available, which enable them to be incorporated within a tiled surface without any concerns about the overall aesthetics. There are several joint materials available, which are designed for use in a range of environments. For example, aluminium joints are ideal for many commercial installations, although for areas of heavy use such as factory environments, a brass or stainless-steel joint should be used. For other environments such as residential use, PVC movement joints are usually sufficient.

Here at Quantum we stock a variety of movement joints, which have been carefully handpicked to ensure we have a supply for every potential tiling project. To find out more about stocking our range of tile movement joints or to find your nearest stockist, please contact the team today.